SIMULATION

Numerical simulations are indispensable in many contexts. Whether it is airflow calculations, heat transfer, turbulent flows or supersonic phenomena, GOLDBERG ANALYTICS offers capabilities and solutions for advanced applications in fluid mechanics and aeroacoustics for industry and medium-sized companies. Our calculations are of fundamental importance for decision-makers in politics and governance. Browse some examples:

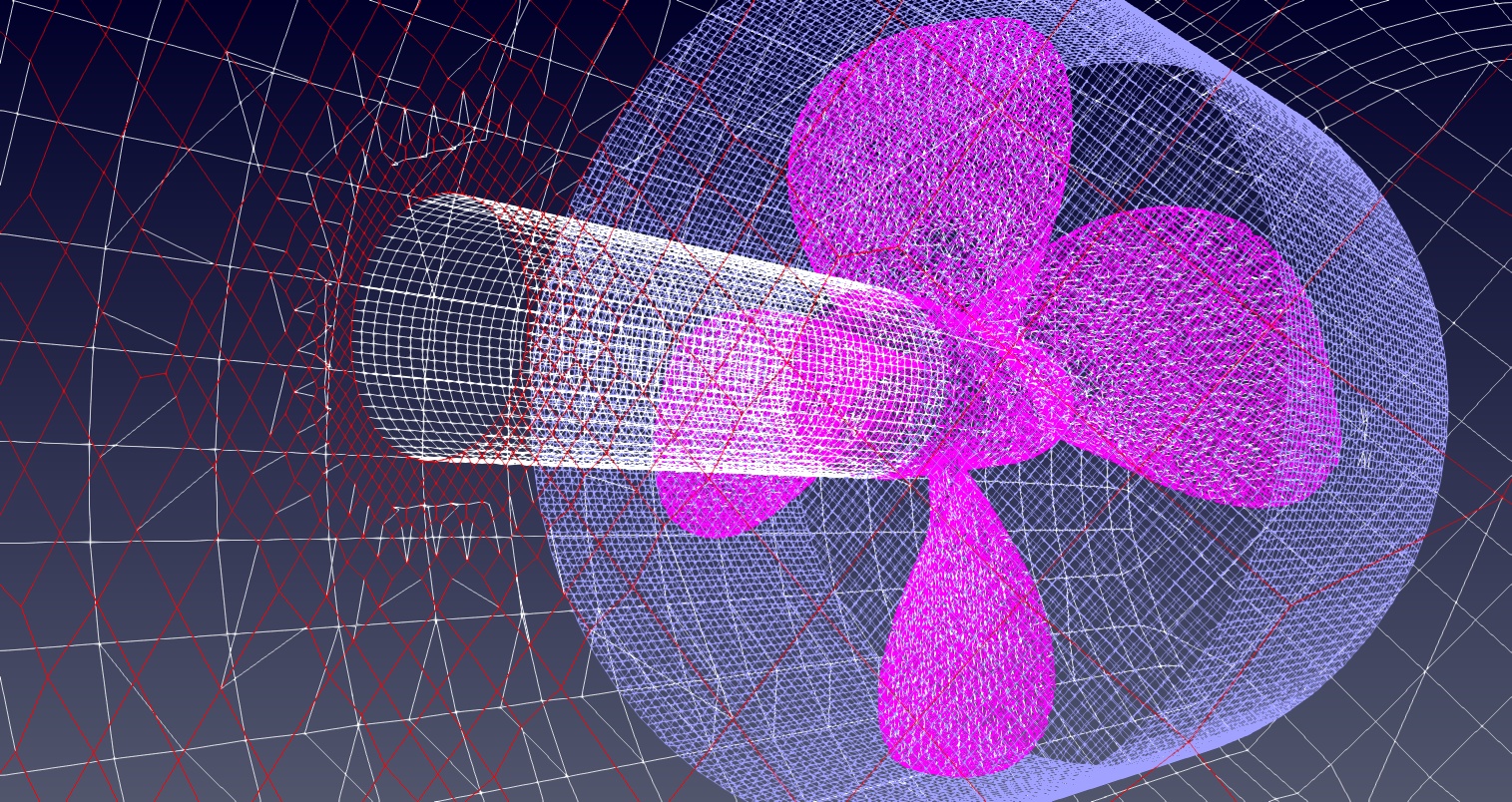

Moving Components

By utilizing particle tracking we quantify turbulent coherent structures in fluid mechanical and aeroacoustical set-ups. Turbulence has many impacts on moving components in air and water flows. GOLDBERG ANALYTICS calculates turbulent flow around rotors of wind turbines or ship propellers.

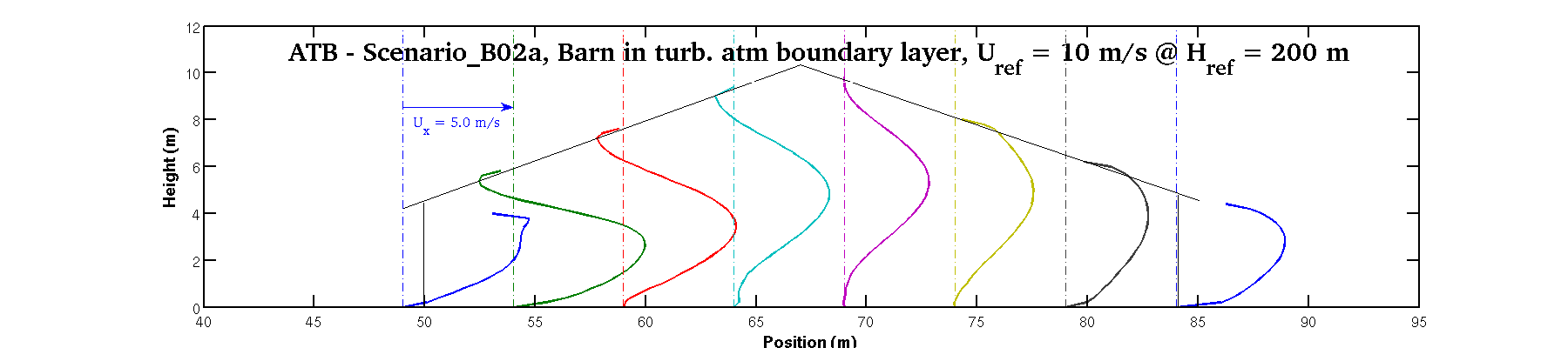

Turbulent Atmospheric Boundary Layers

With methods of numerical simulations GOLDBERG ANALYTICS characterizes transfers of aerosols as well as of vectors of infection disease spreadings. Based on data driven simulations of atmospheric boundary layers we predict roughness parameters which helps to optimize architectural complexes and constructions. With our predictions customers re-design high risk flood areas as well as wind and conflagration zones.

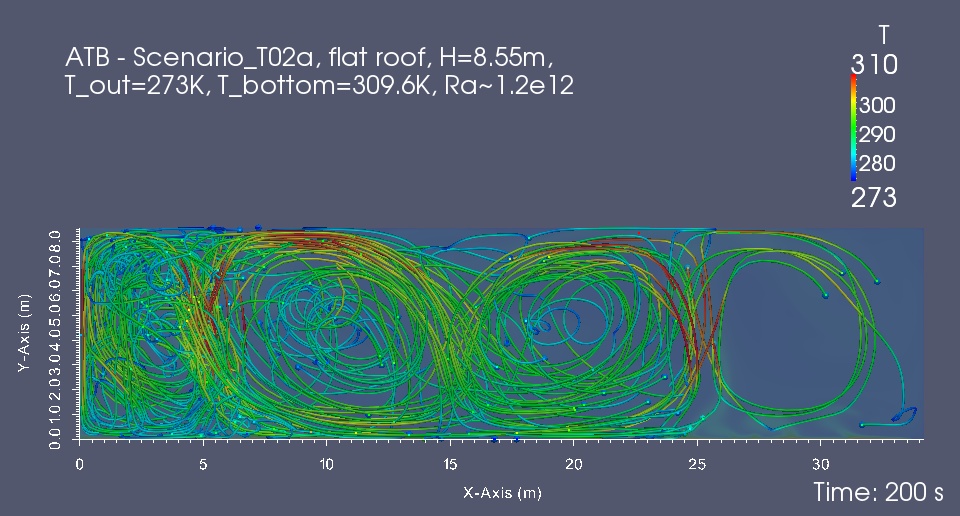

Thermo-induced Turbulent Flows

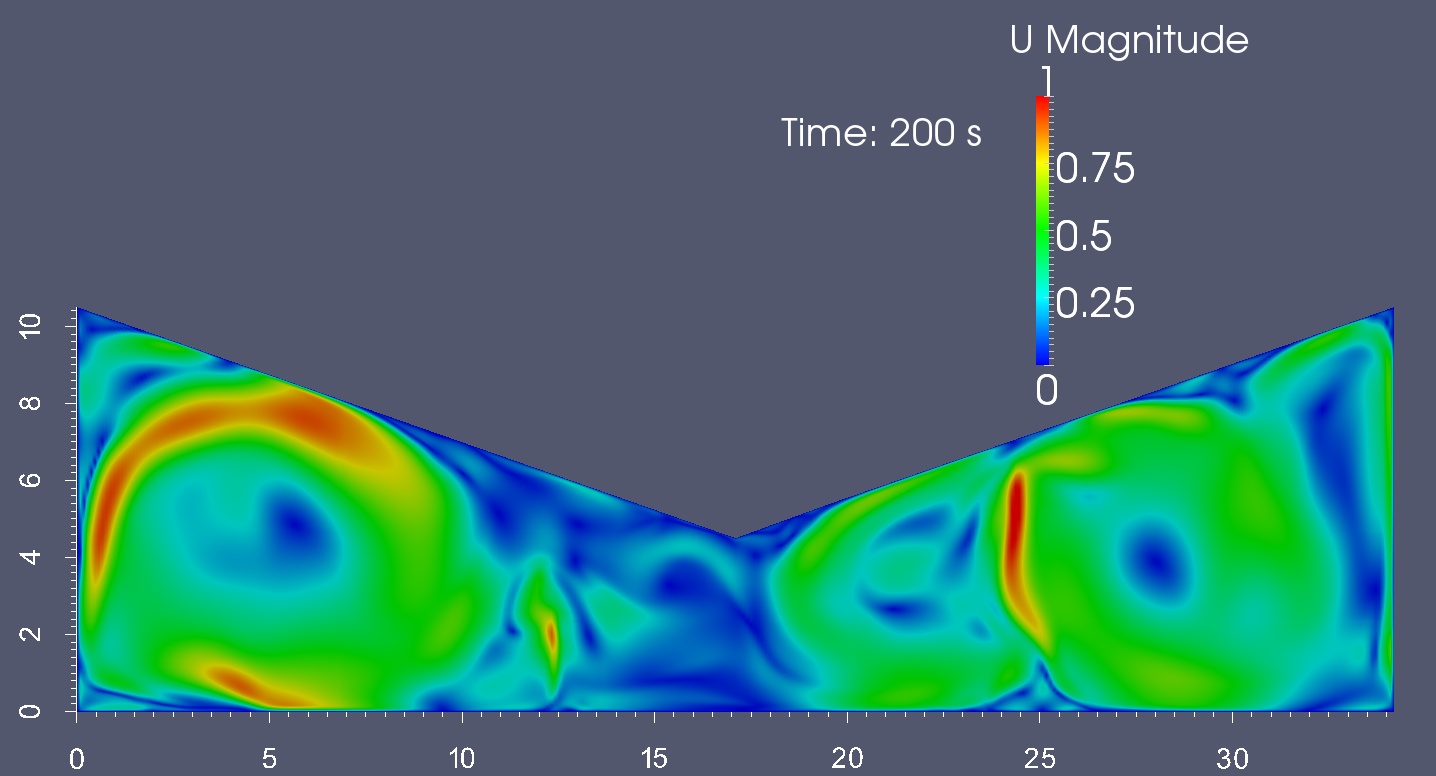

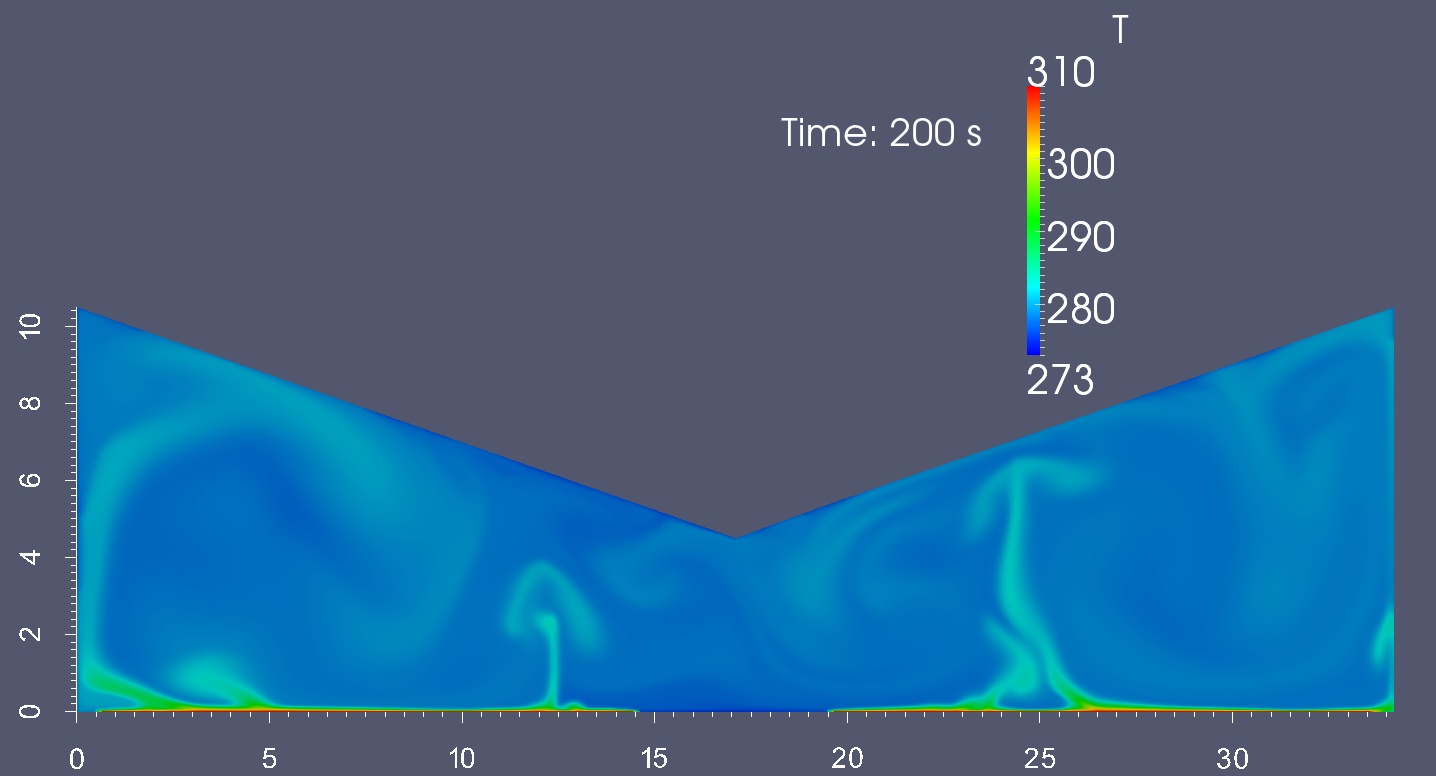

Data-based simulations on thermo-induced air ventilations help to improve room conditions and prevent virus spreading events. This can, for example, help to ensure animal welfare in various lifestock set-ups.

Piched roof: Thermo-induced ventilation (temperature).

Piched roof: Thermo-induced ventilation (velocity).

Aerosols in Different Hanger Constructions

Ventilation in hangers is important to avoid the accumulation of harmful gases. The case study shows different constructions with thermo-induced natural convection. With particle tracking the most critical areas of accumulation can be identified.

Inverse roof: Thermo-induced air convection (velocity).

Inverse roof: Thero-induced air convection (temperature).

Flat roof: Particle tracking of aerosols in a thermo-induced air condition scenario.

Aeroacoustics

One of the tasks of organ builders is to minimize the interaction of organ pipes in stops and swells. Acoustic interactions can destroy the intonation of the instrument. For this reason it is necessary to understand how the synchronization process works within the instruments. Numerical simulations give a deep insight into this nonlinear process. The simulation of aeroacoustic phenomena requires dealing with the fully compressible Navier-Stokes equations.

In some cases geometries have a strong impact on sound generation. This numerical simulation shows the impact of a concarve geometry. Left: The evolution of the sound pressure. Right: The correspondig dynamics of the turbulent kinetic energy of the organ pipe's jet in the sound generator region of the instrument.

Contact us to get in touch with our expertise.